IMARC Group’s report titled “Flow Chemistry Market Report by Reactor (Continuous Stirred Tank Reactor, Plug Flow Reactor, Microreactor, Microwave System, and Others), Application (Pharmaceuticals, Chemicals, Academia and Research, Petrochemicals, and Others), and Region 2024-2032” The global flow chemistry market size reached US$ 1.8 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 4.0 Billion by 2032, exhibiting a growth rate (CAGR) of 8.8% during 2024-2032.

Grab a sample PDF of this report: https://www.imarcgroup.com/flow-chemistry-market/requestsample

Factors Affecting the Growth of the Flow Chemistry Industry:

- Increasing Focus on Productivity:

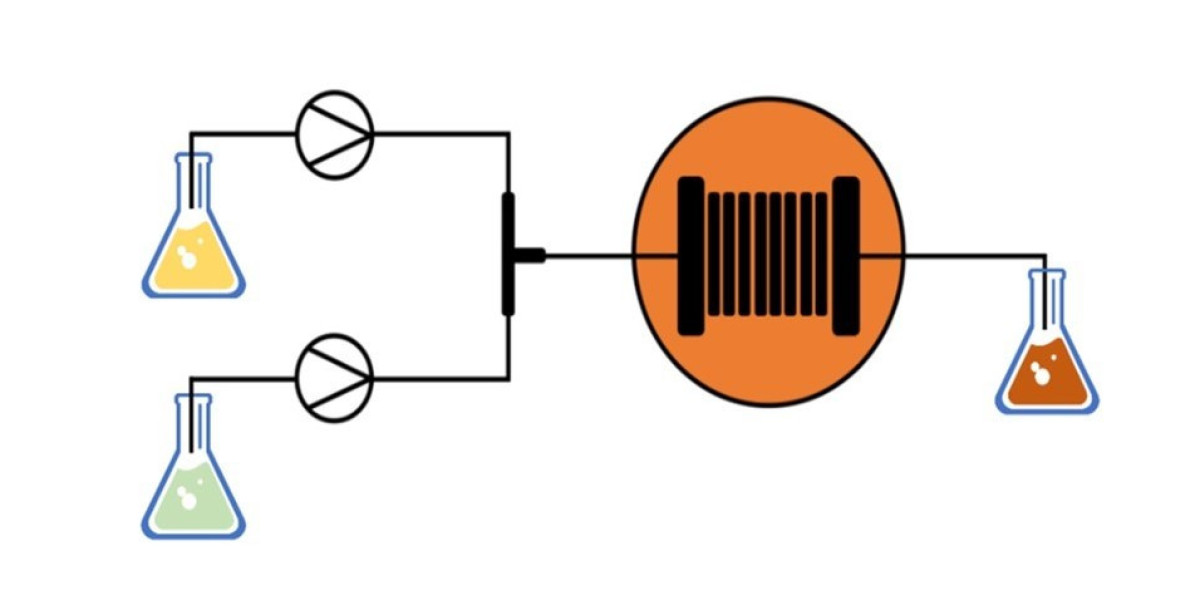

The rising focus on enhanced efficiency and productivity is contributing to the market growth. Flow chemistry allows for the constant feed of reactants into a reactor and the simultaneous collection of output, facilitating uninterrupted chemical synthesis, unlike traditional batch processing. This continuous process not only increases reaction times but also enables a more consistent and scalable production output. Besides this, companies can achieve higher throughput by minimizing the downtime associated with cleaning and setting up batch reactors for new reactions.

- Growing Need for Enhanced Safety:

Flow chemistry benefits in enhancing the safety of chemical manufacturing processes. The methodology involves the use of smaller quantities of chemical reactants and intermediates within confined reactor spaces, reducing the risk of explosive and hazardous reactions as compared to traditional batch reactors. This minimized volume not only mitigates the potential impact of any adverse reaction but also simplifies the handling of volatile or dangerous substances. Additionally, the closed system of flow reactors prevents the release of toxic gases or spills, protecting both the environment and personnel. The inherent safety features of flow chemistry are particularly appealing in industries dealing with highly reactive or toxic compounds.

- Improved Reaction Control:

Flow chemistry systems offer improved control over reaction conditions, such as temperature, pressure, and reaction time, enhancing the selectivity and yield of chemical processes. This precise control is facilitated by the rapid mixing and heat transfer capabilities of flow reactors, allowing for immediate adjustments to reaction parameters in response to real-time monitoring. Such control enables the fine-tuning of reaction pathways, leading to the discovery of more efficient routes or novel products. Moreover, the ability to maintain consistent reaction conditions ensures reproducibility and scalability. This level of control is vital in industries where product quality and consistency are critical, such as pharmaceuticals.

Leading Companies Operating in the Global Flow Chemistry Industry:

- AM Technology

- Chemtrix BV

- Corning Incorporated

- Ehrfeld Mikrotechnik GmbH

- FutureChemistry Holding B.V.

- HEL Ltd.

- Lonza Group AG

- Milestone Srl

- Parr Instruments Company

- Syrris Ltd (Asahi Glassplant Inc.)

- ThalesNano Inc

Flow Chemistry Market Report Segmentation:

By Reactor:

- Continuous Stirred Tank Reactor

- Plug Flow Reactor

- Microreactor

- Microwave System

- Others

Continuous stirred tank reactor represents the largest segment as it maintains a steady-state operation while allowing for efficient mixing and reaction control.

By Application:

- Pharmaceuticals

- Chemicals

- Academia and Research

- Petrochemicals

- Others

Chemicals hold the biggest market share due to the rising focus on optimizing reaction conditions and minimizing waste.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America enjoys a leading position in the flow chemistry market, which can be attributed to the burgeoning pharmaceutical sector.

Global Flow Chemistry Market Trends:

Flow chemistry can contribute to more sustainable chemical processes by reducing solvent use and energy consumption and by enabling more efficient use of resources. This aligns with the rising focus on green chemistry and sustainable industrial practices. Furthermore, the increasing adoption of flow chemistry, as it lowers energy and raw material consumption, labor costs, and the need for large-scale industrial plants, is bolstering the market growth.

Advancements in flow chemistry technology, including new reactor designs and enhanced process monitoring and control systems, are supporting the market growth.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163