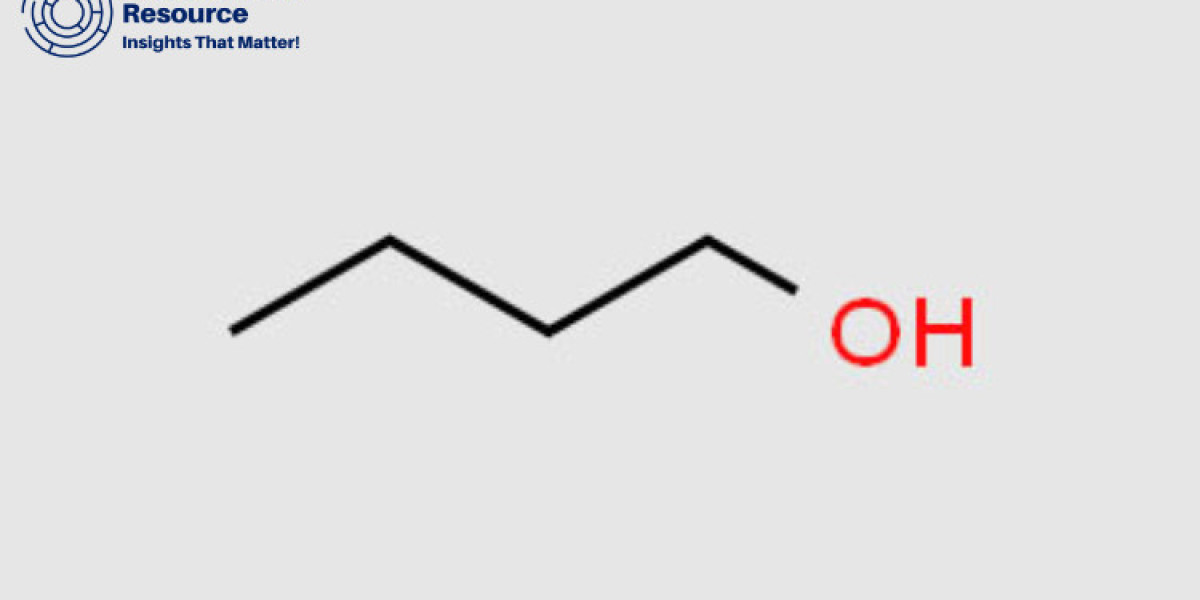

Butanol, a four-carbon alcohol, has garnered significant attention due to its versatile applications in various industries, ranging from biofuels to solvents. The production of butanol involves complex chemical processes, leveraging different raw materials and methodologies. This report aims to provide a detailed overview of the butanol production process, including the manufacturing steps, raw material costs, and the latest industry news.

Manufacturing Report and Process

The production of butanol can be achieved through several methods, with the two most prominent being petrochemical synthesis and biological fermentation. Each method has its own set of procedures, advantages, and challenges.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/butanol/request-sample

1. Petrochemical Synthesis

Petrochemical synthesis involves the production of butanol from fossil fuels. The primary process used is the oxo process (hydroformylation), which can be summarized as follows:

a. Oxo Process (Hydroformylation)

- Feedstock Preparation: The process begins with the preparation of feedstocks, primarily propylene derived from crude oil refining or natural gas processing.

- Hydroformylation: Propylene reacts with synthesis gas (a mixture of carbon monoxide and hydrogen) in the presence of a rhodium or cobalt catalyst to form butyraldehyde.

- Hydrogenation: Butyraldehyde is then hydrogenated to produce butanol.

- Distillation: The final step involves the distillation of butanol to achieve the desired purity levels.

2. Biological Fermentation

Biological fermentation offers a more sustainable and eco-friendly alternative to petrochemical synthesis. This method utilizes microorganisms to convert biomass into butanol. The primary steps include:

a. Fermentation

- Substrate Preparation: Biomass such as corn, sugarcane, or agricultural waste is pre-treated to release fermentable sugars.

- Microbial Fermentation: Specific strains of Clostridium bacteria (e.g., Clostridium acetobutylicum) are employed to ferment the sugars into a mixture of acetone, butanol, and ethanol (ABE fermentation).

- Product Recovery: The fermentation broth undergoes distillation and solvent extraction to separate and purify butanol.

Raw Material Costs

The cost of raw materials significantly impacts the overall economics of butanol production. Understanding these costs is crucial for optimizing production processes and maintaining profitability.

1. Petrochemical Feedstocks

- Propylene: As the primary feedstock for the oxo process, the price of propylene is influenced by the global supply and demand dynamics of crude oil and natural gas. Market fluctuations can lead to significant variations in propylene costs.

- Synthesis Gas: Comprising carbon monoxide and hydrogen, synthesis gas is typically produced from natural gas or coal. The cost of natural gas and coal, therefore, directly affects the production cost of synthesis gas.

2. Biomass Feedstocks

- Corn and Sugarcane: These are the most commonly used feedstocks for biological fermentation. Their prices are subject to agricultural market trends, climate conditions, and regional supply.

- Agricultural Waste: Utilizing agricultural waste as a feedstock can reduce costs and enhance sustainability. However, the collection, transportation, and pre-treatment of waste materials incur additional expenses.

3. Catalysts and Microorganisms

- Catalysts: In petrochemical synthesis, the cost of catalysts (e.g., rhodium, cobalt) is a significant factor. These catalysts are often expensive and require careful management to maintain their efficacy.

- Microorganisms: For biological fermentation, the cost of cultivating and maintaining microbial strains can influence overall production expenses. Genetic engineering and optimization of microbial strains are ongoing efforts to improve cost efficiency.

Latest News

The butanol production industry is dynamic, with continuous advancements and market developments. Staying informed about the latest news is essential for industry stakeholders to make informed decisions and adapt to changing trends.

1. Technological Innovations

Recent technological advancements have focused on improving the efficiency and sustainability of butanol production. For instance, researchers are exploring new microbial strains and genetic modifications to enhance fermentation yields. Additionally, advancements in catalyst development aim to reduce costs and increase the selectivity of petrochemical processes.

2. Market Trends

The demand for butanol as a biofuel has been on the rise, driven by the need for renewable energy sources. Governments and regulatory bodies are increasingly supporting the use of biofuels to reduce greenhouse gas emissions. This shift is creating new opportunities and challenges for butanol producers.

3. Sustainability Initiatives

Sustainability is a key driver in the butanol production industry. Companies are adopting green chemistry principles and circular economy practices to minimize environmental impact. This includes utilizing renewable feedstocks, reducing waste, and optimizing energy consumption.

4. Economic Factors

Global economic conditions, trade policies, and geopolitical events can significantly impact the butanol market. For example, fluctuations in crude oil prices can affect the competitiveness of petrochemical synthesis compared to biological fermentation. Monitoring these factors is crucial for strategic planning and risk management.

5. Regulatory Developments

Regulatory changes can have profound effects on the butanol industry. Governments are implementing stricter environmental regulations, which may require producers to adopt cleaner production technologies. Compliance with these regulations can lead to increased operational costs but also opens opportunities for innovation and differentiation.

Conclusion

The butanol production process is multifaceted, involving intricate chemical reactions and diverse raw materials. Both petrochemical synthesis and biological fermentation offer viable pathways, each with its own set of challenges and benefits. Understanding the cost dynamics of raw materials and staying abreast of the latest industry news is essential for navigating the evolving landscape of butanol production. As the demand for sustainable and renewable energy sources grows, the butanol industry is poised for significant advancements and opportunities.