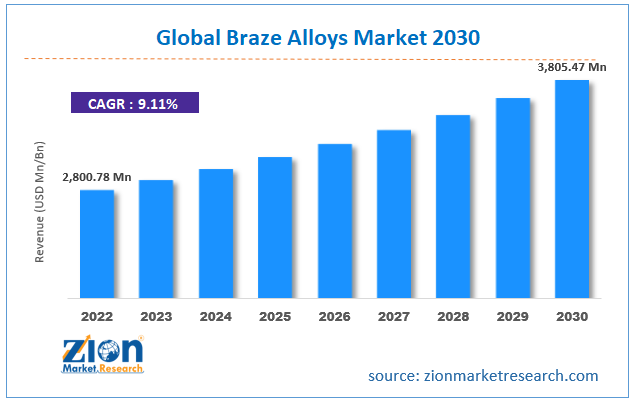

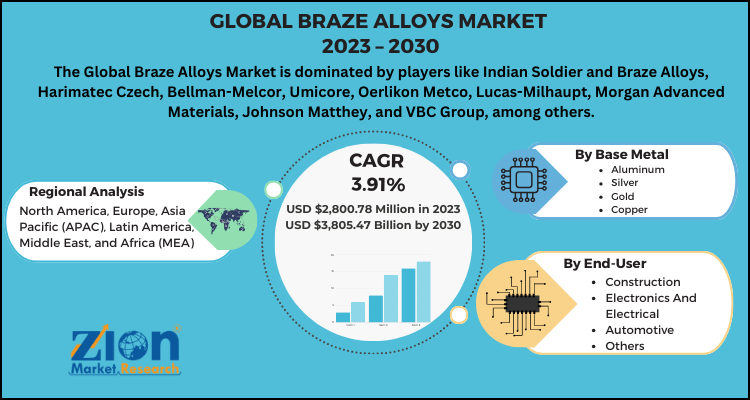

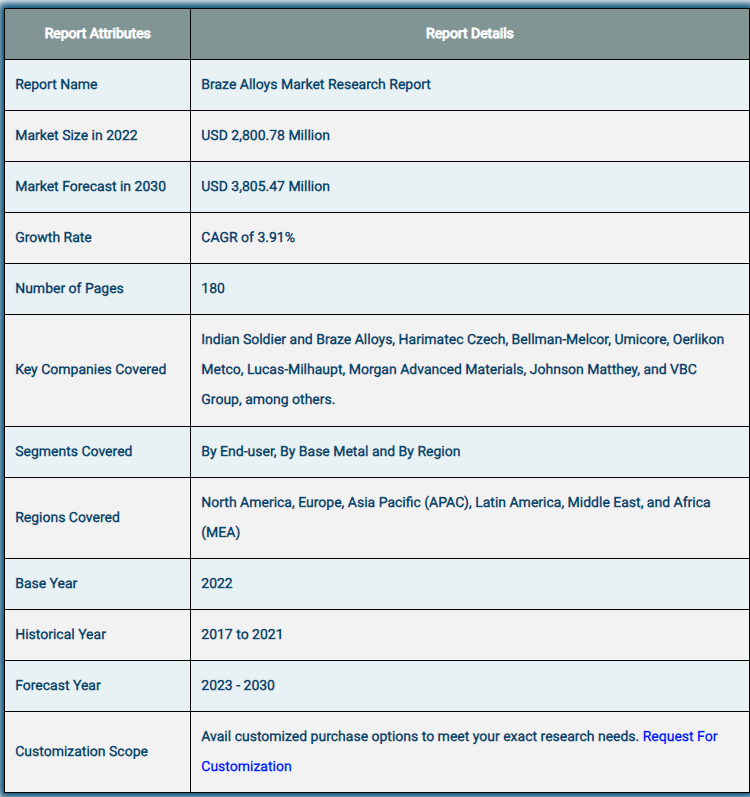

The global braze alloys market was estimated to be worth USD 2,800.78 million in 2024 and is expected to grow to USD 3,805.47 million by the end of 2032, according to a report released by Zion Market Research. Over the course of the projection period, the market is anticipated to expand at a CAGR of 3.91%. The growth prospects, challenges, and effects on demand of the worldwide braze alloys market are examined in this study for the period of forecasting. Additionally, it will support exploration and navigation of the emerging opportunities in the Braze Alloys Market sector.

Introduction

Braze alloys play a critical role in industries where joining metals with precision and durability is essential. They are commonly used in applications such as aerospace, automotive, electronics, and construction. Braze alloys offer advantages such as high strength, corrosion resistance, and the ability to join dissimilar metals without melting the base materials. As industries continue to evolve, the braze alloys market is witnessing significant growth, driven by technological advancements and increased demand from various sectors.

Overview of the Global Braze Alloys Market

The global braze alloys market has experienced steady growth in recent years, and it is expected to continue expanding. This growth is largely attributed to the rising adoption of brazing techniques in key industries, including automotive manufacturing, aerospace, and electronics. The demand for brazing in heat exchangers, HVAC systems, and advanced industrial machinery is also contributing to market expansion.

Key braze alloys include silver, copper, aluminum, gold, and nickel-based alloys, each catering to specific industry needs. These materials offer high thermal conductivity, excellent mechanical properties, and resistance to environmental degradation, making them ideal for demanding applications.

Brazing is the process of connecting two or more metals together by melting them and then filling the joint with another metal that has melted. The braze alloy, also known as the filler metal, lowers the melting point of the primary metals used in brazing. The melting point of a braze alloy is often higher than 450°C. The temperature shouldn’t, however, exceed the melting point of the relevant base metals. Braze alloys can be used as paste, foil, powder, braze wires, rods, and tapes, among other forms. The increasing use of braze alloys for a variety of applications across several end-user sectors is responsible for the market’s demand and popularity for these materials worldwide.

Braze Alloys Market Worldwide: Growth Drivers

The growing preference for brazing over soldering, welding, etc. for joining metals in a variety of end-user sectors worldwide will be the primary growth driver of the global braze alloys market in the future. A few benefits of brazing include its low cost, ductility, self-fluxing nature, high electrical conductivity, and capacity to combine metals with a variety of components. In turn, this is expected to fuel the global market for braze alloys’ expansion in the years to come. Other factors that are anticipated to have a major impact on the growth of the braze alloys market globally in the coming years include the increasing production of automobiles and their various components as well as the expanding use of brazed parts by the electrical and electronics industries.

Segmentation of the Global Braze Alloys Market

The base metal and end-user industries make up the two segments of the global braze alloys market. This global market is divided into the end-user industries of construction, automotive, electronics and electrical, and others (medical, dentistry, and aerospace). Due to the widespread use of brazing in condenser and evaporator connections for fuel injection pipes, air conditioners, and brake linings, the automotive industry is anticipated to dominate this global market during the forecast period. The global braze alloys market comprises copper, aluminium, silver, gold, and other base metals (such as nickel and palladium). Because of their exceptional resistance to corrosion and good thermal and electrical conductivity, copper-based braze alloys are widely employed in a variety of end-user sectors.

Braze Alloys Market: Extent of the Report

Regional Analysis of the Global Braze Alloys Market

This global market is mainly divided into five regions: Europe, Latin America, Asia Pacific, North America, and the Middle East and Africa. The braze alloys market is anticipated to grow at a significant rate in the Asia Pacific area in the coming years. The thriving automotive sector in the Asia Pacific area can be ascribed to the augmented investments made by prominent firms in car manufacturing. Significant expenditures made in the construction of commercial, residential, and industrial zones throughout the region are contributing factors to the growth of this regional market. Since the braze alloy markets in North America and Europe are developed, their growth rates are expected to be slow during the projected period. It is projected that in the future, the United States will account for a sizable portion of the North American braze alloys market.

Key Market Drivers

- Growing Demand in the Automotive Industry: The automotive sector is a major consumer of braze alloys, particularly in the production of heat exchangers, fuel systems, and exhaust systems. The growing trend toward electric vehicles (EVs) and hybrid vehicles further fuels demand for efficient brazing techniques, especially in battery cooling systems and lightweight material assembly.

- Technological Advancements in Aerospace: In the aerospace industry, the need for lightweight, durable materials has led to the increased use of braze alloys in critical components. Nickel-based braze alloys, in particular, are widely used for joining superalloys in turbine blades, engine parts, and structural assemblies due to their ability to withstand extreme temperatures.

- Rising Applications in Electronics: With the miniaturization of electronic devices and the growing demand for high-performance components, brazing techniques are becoming more prevalent in the electronics sector. Braze alloys are essential for joining delicate components without damaging them, ensuring reliability in consumer electronics, semiconductors, and telecommunications equipment.

- Industrial Automation and HVAC Systems: The manufacturing industry, driven by automation and precision engineering, increasingly relies on braze alloys for assembling complex components. Additionally, the HVAC industry continues to expand due to the rising demand for energy-efficient systems, creating a growing need for brazing in heat exchangers and cooling systems.

Challenges in the Braze Alloys Market

While the braze alloys market is growing, it faces several challenges:

- Volatility in Raw Material Prices: Many braze alloys, especially silver-based ones, are subject to fluctuations in raw material prices. This price volatility can impact production costs and profit margins for manufacturers.

- Environmental and Health Concerns: The use of certain brazing materials and processes can raise environmental and health concerns. Lead-based alloys, for example, have been restricted in many regions due to their toxic effects, prompting the industry to shift towards more environmentally friendly alternatives.

- Technical Expertise: Brazing requires skilled operators and precise control over temperature and material selection. The lack of trained professionals in certain regions can limit market expansion, particularly in emerging economies.

Regional Analysis

The braze alloys market is globally distributed, with key regions including North America, Europe, Asia-Pacific, and Latin America. Each region has its own market dynamics, driven by industrial growth, regulatory frameworks, and technological adoption.

- North America: The region remains a dominant player due to the strong presence of automotive and aerospace industries. The demand for braze alloys in defense and infrastructure projects further drives market growth.

- Europe: Europe’s focus on green technologies and energy-efficient solutions is contributing to the demand for braze alloys, particularly in renewable energy projects and electric vehicle production.

- Asia-Pacific: Asia-Pacific is one of the fastest-growing markets, fueled by rapid industrialization in countries like China, India, and Japan. The region’s booming electronics and automotive sectors are key drivers for braze alloy demand.

Competitive Landscape

The braze alloys market is highly competitive, with several key players leading innovation and expansion efforts. Major companies such as Lucas-Milhaupt, Umicore, Harris Products Group, and Morgan Advanced Materials are investing in research and development to introduce new braze alloy formulations that cater to emerging market needs.

- Product Innovation: Many companies are focusing on developing lead-free and environmentally friendly braze alloys to comply with regulatory standards. Advanced alloys with enhanced temperature resistance and corrosion protection are being introduced to meet the demands of high-tech industries.

- Strategic Partnerships: Collaborations between braze alloy manufacturers and end-user industries are becoming more common. For example, partnerships between alloy producers and automotive or aerospace companies allow for customized solutions tailored to specific application requirements.

Future Outlook

The braze alloys market is poised for continued growth, driven by the increasing demand for brazing techniques in high-performance applications. Technological advancements, such as automated brazing systems and the development of new alloys, will further enhance the market’s potential.

As industries shift toward lightweight materials and energy-efficient solutions, the demand for braze alloys will rise across sectors such as automotive, aerospace, electronics, and industrial manufacturing. Additionally, the push for sustainable and environmentally friendly brazing solutions will encourage innovation and create new opportunities for market players.

Conclusion

The braze alloys market is a dynamic and evolving space, with strong growth prospects in the coming years. Driven by key industries such as automotive, aerospace, and electronics, braze alloys will continue to play a critical role in high-performance, precision joining applications. While challenges such as raw material price fluctuations and environmental concerns exist, ongoing innovation and strategic collaborations will drive the market forward, ensuring its sustained growth across the globe.

Contact Us:

Zion Market Research212

USA/Canada Toll Free: 1 (855) 465–4651

Newark: 1 (302) 444–016611\s

Web: https://www.zionmarketresearch.com/

Blog: https://zmrblog.com/