For efficient metal cutting, machining data, tools and cutting conditions are the three major elements. These determine the machining time, tool life and machining quality. An economical and effective machining method must be a reasonable choice of cutting conditions.

Three factors of cutting conditions: cutting speed, feed rate and depth of cutting directly cause tool damage. As the cutting speed increases, the temperature of the tip increases, and mechanical, chemical, and thermal wear occurs. A 20% increase in cutting speed can reduce tool life by half.

The relationship between feed conditions and tool wear occurs on a small scale. However, the feed rate is large, the cutting temperature is increased, and the back wear is large. It has less effect on the tool than the cutting speed. The effect of cutting depth on the tool is not cutting speed and feed, but in the micro cutting depth, the rigid layer generated by cutting parameters will also affect the life of the tool.

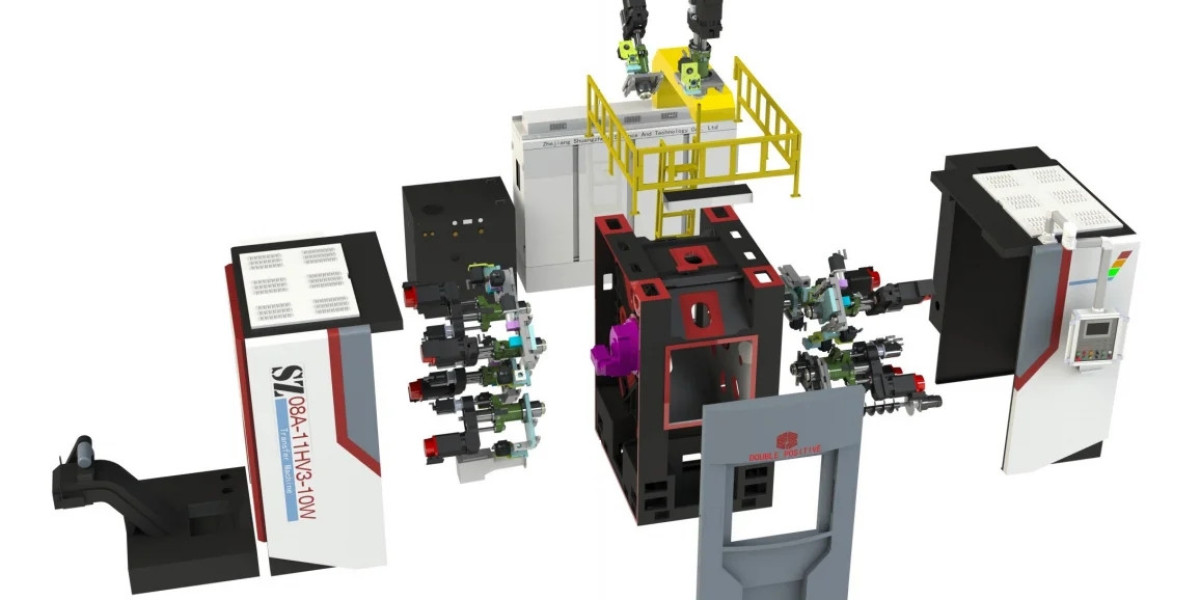

Users should choose cutting speed according to Rotary Table Intelligent Assembly Machine machining data, hardness, cutting state, data variety, feed rate, cutting depth, etc. Select the most suitable processing conditions according to these elements. Regular and steady wear is the ideal condition. But in practice, the choice of tool life is related to tool wear, machining size change, surface quality, cutting noise, processing heat and other factors. Stop the discussion on the basis of confirming the processing conditions and requirements. For refractory materials such as stainless steel and heat-resistant alloys, coolant or rigid blades can be used.

Rotary Table Intelligent Assembly Machine https://www.zjshuangzheng.com/Rotary-Table-Intelligent-Assembly-Machine.html