This blog delves into the current trends and innovations shaping the ID card manufacturing industry, focusing on how these developments are being embraced by dealers and manufacturers in Odisha, particularly in Bhubaneswar.

Introduction to ID Card Manufacturing

ID cards have become an indispensable part of security and identification systems across various sectors. From corporate offices and educational institutions to government agencies and healthcare facilities, ID cards serve as essential tools for authentication, access control, and personalization. As the demand for secure and high-quality ID cards continues to grow, manufacturers and dealers are continually seeking ways to enhance their offerings through technological advancements and innovative practices.

The Evolution of ID Card Manufacturing in Odisha

Odisha, known for its rich cultural heritage and industrial prowess, has emerged as a significant hub for ID card manufacturing in recent years. The state's dealers and manufacturers have adopted cutting-edge technologies and embraced global trends to meet the increasing demands of their clients. As a result, Odisha is now home to some of the most advanced ID card manufacturing facilities in India.

Key Trends in ID Card Manufacturing

1. Advanced Printing Techniques

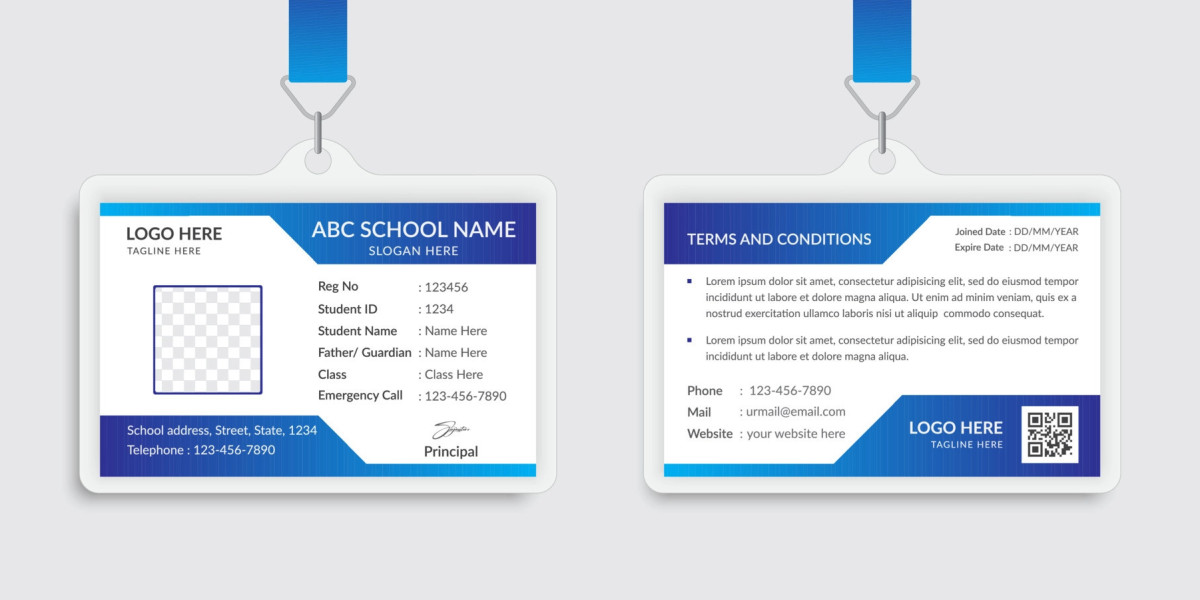

One of the most notable trends in ID card manufacturing is the adoption of advanced printing techniques. Traditional printing methods are being replaced by digital printing technologies, such as dye-sublimation and retransfer printing. These methods offer several advantages, including higher resolution, vibrant colors, and enhanced durability. By utilizing these advanced techniques, ID card dealers in Bhubaneswar can offer cards with superior print quality and intricate designs.

2. Enhanced Security Features

As security concerns continue to rise, the need for ID cards with robust security features has become paramount. Modern ID cards incorporate various security elements to prevent counterfeiting and unauthorized access. Some of the key security features include:

- Holograms: These three-dimensional images provide a high level of visual security and are difficult to replicate.

- UV Printing: Invisible under normal light, UV-printed elements become visible under ultraviolet light, adding an extra layer of security.

- Microtext: Tiny text that is challenging to reproduce, providing an additional barrier against counterfeiting.

- Smart Chips and RFID: These embedded technologies enable contactless communication and data storage, enhancing both security and functionality.

3. Eco-Friendly Materials

Sustainability has become a crucial consideration in ID card manufacturing. Many manufacturers in Odisha are now opting for eco-friendly materials, such as recycled PVC and biodegradable substrates. These materials help reduce the environmental impact of ID card production while maintaining the same level of quality and durability. Additionally, some manufacturers are exploring the use of plant-based plastics and other sustainable alternatives.

4. Personalization and Customization

With the increasing demand for personalized identification solutions, ID card dealers in Bhubaneswar are offering a wide range of customization options. From personalized photos and logos to unique card shapes and colors, clients can now design ID cards that reflect their brand identity and meet specific requirements. Advanced printing technologies enable manufacturers to produce highly customized cards with precision and efficiency.

Technological Advancements in ID Card Manufacturing

1. Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing the ID card manufacturing process. These technologies are being used to enhance various aspects of production, from design and printing to quality control and security. AI-powered software can analyze complex data sets to detect anomalies and ensure the highest level of accuracy in card production. Additionally, ML algorithms can predict trends and optimize manufacturing processes, leading to improved efficiency and reduced costs.

2. Internet of Things (IoT)

The Internet of Things (IoT) is transforming the way ID cards are used and managed. IoT-enabled ID cards can communicate with other smart devices and systems, allowing for seamless integration and real-time data exchange. For example, IoT-enabled access control systems can monitor and manage entry points more effectively, enhancing overall security. In Odisha, manufacturers are incorporating IoT technology into their ID card solutions to provide clients with cutting-edge, interconnected systems.

3. Blockchain Technology

Blockchain technology is gaining traction in the ID card manufacturing industry due to its potential to enhance security and transparency. By leveraging blockchain, manufacturers can create tamper-proof digital records of each ID card, ensuring that any changes or transactions are securely logged and traceable. This technology is particularly useful for government agencies and organizations that require a high level of data integrity and security. ID Card Dealers in Bhubaneswar are exploring the implementation of blockchain to offer clients a more secure and reliable identification solution.

4. Cloud-Based Solutions

Cloud computing is enabling ID card manufacturers to streamline their operations and improve service delivery. Cloud-based solutions provide a centralized platform for managing design files, production schedules, and client data. This approach allows manufacturers to collaborate more effectively, access real-time information, and scale their operations as needed. In Odisha, many ID card manufacturers are adopting cloud-based systems to enhance efficiency and provide clients with faster, more reliable service.

The Role of Automation in ID Card Manufacturing

Automation is playing a crucial role in the advancement of ID card manufacturing. Automated systems and machinery are being used to perform various tasks, such as printing, cutting, encoding, and quality control. The benefits of automation include:

- Increased Productivity: Automated systems can operate continuously, significantly boosting production capacity.

- Enhanced Precision: Automation reduces the risk of human error, ensuring consistent quality and accuracy.

- Cost Savings: By reducing labor costs and minimizing waste, automation can lead to significant cost savings for manufacturers.

- Improved Safety: Automated machinery can handle hazardous tasks, reducing the risk of injury for workers.

Case Study: Technological Integration in Odisha's ID Card Manufacturing

To illustrate the impact of these trends and advancements, let's take a closer look at a leading ID card dealer in Bhubaneswar. This dealer has successfully integrated advanced printing techniques, AI-driven quality control, and IoT-enabled access control systems into their product offerings. By embracing these technologies, they have been able to:

- Enhance Product Quality: The use of high-resolution digital printing and AI-powered quality control has resulted in ID cards with exceptional print quality and precision.

- Increase Security: The incorporation of IoT and blockchain technology has provided clients with highly secure and tamper-proof identification solutions.

- Boost Efficiency: Automation and cloud-based systems have streamlined production, allowing for faster turnaround times and improved service delivery.

- Promote Sustainability: The use of eco-friendly materials and sustainable practices has reduced the environmental impact of their manufacturing process.

The Future of ID Card Manufacturing in Odisha

The ID card manufacturing industry in Odisha is poised for continued growth and innovation. As technology continues to evolve, manufacturers will have even more opportunities to enhance their products and services. Some potential future developments include:

- Biometric Integration: The incorporation of biometric data, such as fingerprints and facial recognition, into ID cards for enhanced security and authentication.

- Augmented Reality (AR): The use of AR technology to create interactive ID cards that can display additional information or provide access to digital content.

- 3D Printing: The adoption of 3D printing techniques to produce ID cards with unique shapes, textures, and embedded components.

Conclusion

The ID card manufacturing industry in Odisha is experiencing a transformative phase, driven by the latest trends and technological advancements. From advanced printing techniques and enhanced security features to AI-driven automation and IoT integration, manufacturers are continually pushing the boundaries to provide clients with innovative and high-quality identification solutions. As one of the leading ID Card Manufacturers in Odisha, we are committed to staying at the forefront of these developments, ensuring that our clients receive the best possible products and services.

By embracing these trends and technologies, ID card dealers in Bhubaneswar are well-positioned to meet the evolving needs of their clients and maintain their competitive edge in the global market. As we look to the future, the possibilities for further innovation and growth in this industry are limitless, promising even more exciting advancements in the years to come.