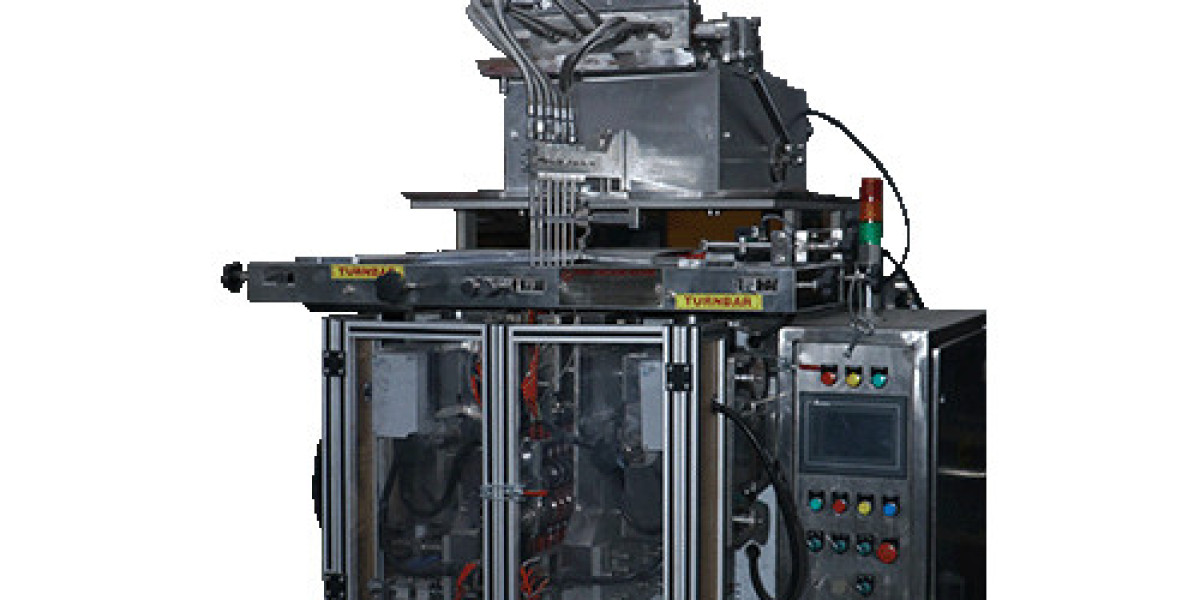

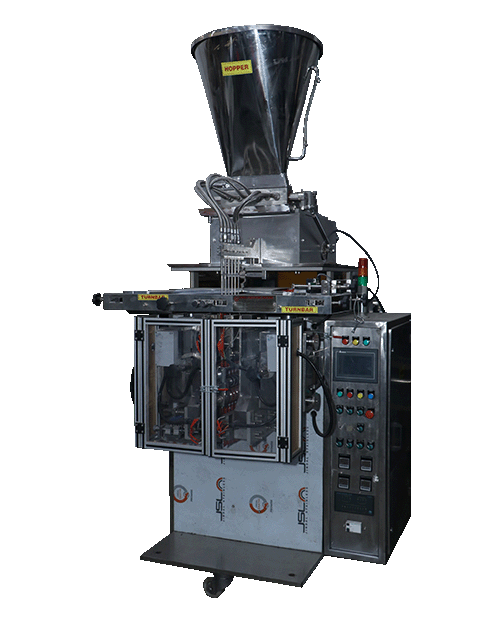

Durga Packaging Machine The Shampoo Pouch Packing Machine is a sophisticated piece of equipment that automates the process of filling and sealing liquid products, such as shampoo, into pouches. This machine is essential for the efficient and hygienic packaging of these products. This blog will delve into the key components that make up this machine.

Understanding the Shampoo Pouch Packing Machine

A Shampoo Pouch Packing Machine is designed to handle the entire packaging process, from feeding the film to outputting the finished pouches. It consists of several interconnected components that work together to achieve optimal performance.

Core Components of the Machine

Film Feeding System: This component is responsible for accurately feeding the packaging film into the machine. It ensures a smooth and uninterrupted supply of film to the subsequent stages.

Pouch Forming Unit: Here, the film is transformed into pouches of the desired size and shape. This unit utilizes precise mechanisms to create the pouch structure.

Filling System: This is where the shampoo is accurately filled into the formed pouches. The filling system can be volumetric or weight-based, depending on the desired precision.

Sealing Unit: Once filled, the pouches are sealed to preserve the product. The sealing unit employs heat or ultrasonic technology to create strong and airtight seals.

Coding and Printing Unit: For product identification and batch information, the machine often includes a coding and printing unit. This component can print essential details directly onto the pouches.

Output Conveyor: The finished pouches are transported to the output conveyor for further processing or packaging.

Additional Components

- Control System: The entire machine is controlled by a sophisticated control system, typically a PLC (Programmable Logic Controller). It manages all functions and parameters.

- Sensors: Various sensors monitor different aspects of the packaging process, such as film presence, pouch formation, filling level, and seal quality.

- Drive System: Motors and gearboxes provide the necessary power to operate the different components of the machine.

Benefits of Using a Shampoo Pouch Packing Machine

- Increased Efficiency: Automation significantly boosts production speed and reduces labor costs.

- Improved Hygiene: The machine minimizes human contact with the product, ensuring hygienic packaging.

- Consistent Pouch Quality: Uniform pouch size and seal quality are maintained.

- Versatility: Many machines can handle different product viscosities and pouch sizes.

By understanding the key components of a Shampoo Pouch Packing Machine, businesses can make informed decisions when selecting and operating this essential piece of packaging equipment.

Durga Packaging Machine is India's leading manufacturer of Shampoo Pouch Packing Machine. You can contact them for further information regarding the Shampoo Pouch Packing Machine at