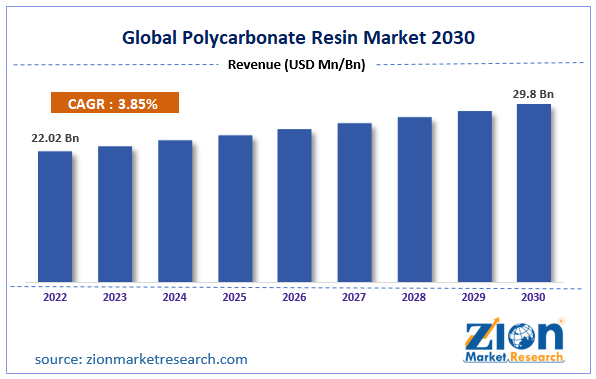

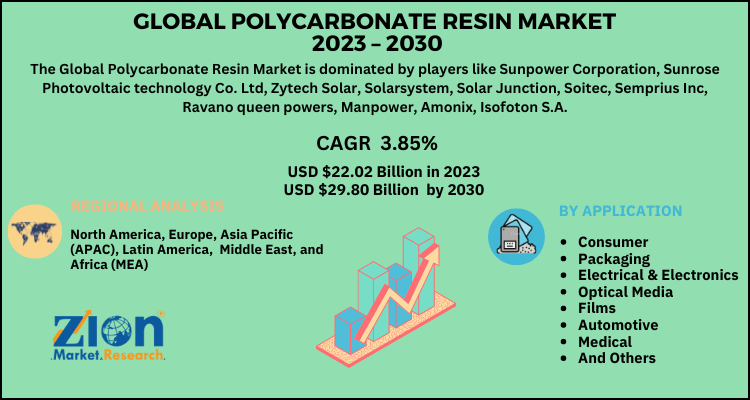

The size of the global polycarbonate resin market was estimated to be about USD 22.02 billion in 2024, and it is expected to increase at a compound annual growth rate (CAGR) of roughly 3.85% between 2024 and 2032 to be around USD 29.80 billion. The study examines the drivers, obstacles, and difficulties facing the global polycarbonate resin market as well as how they will affect demand during the forecast period. The paper also looks at new developments in the polycarbonate resin market.

Introduction

Polycarbonate resin is a high-performance thermoplastic known for its excellent strength, transparency, and impact resistance. It is widely used across various industries, including automotive, electronics, construction, and healthcare, owing to its versatility and durability. The polycarbonate resin market has experienced significant growth, driven by increasing demand for lightweight and high-performance materials. This research article explores the trends, market dynamics, key drivers, challenges, and future outlook of the polycarbonate resin market.

Overview of the Global Polycarbonate Resin Market

The global polycarbonate resin market is poised for robust growth due to the rising demand for lightweight materials in various applications. Polycarbonate resins are utilized in the manufacturing of components such as lenses, safety glasses, automotive parts, and electronic devices. The increasing focus on energy efficiency and sustainability further boosts the demand for polycarbonate materials.

Thermoplastic polycarbonate resins are made of phosgene and bisphenol A. They are amorphous and possess a number of qualities, including high strength and ductility. Phosgene and bisphenol A condensation is the method used to create these resins. Applications for polycarbonate resins have been found in a variety of industries, including automotive, electrical, medical, films, and roofing. Polycarbonate resins are widely used in the automobile industry and on Blu-ray discs. High temperature resistance, transparency, and hardness make polycarbonate resins ideal for transparent applications where security is of utmost importance.

Growth Factors for the Global Polycarbonate Resin Market

Future growth in the polycarbonate resin market is anticipated to be driven by expansion and advancement in the electronics and automotive sectors. The need for eco-friendly products and increasing plastic use will drive the worldwide polycarbonate resin market. They have an advantage over conventional materials like PET, metal, PE, and PVC because to their higher physical qualities, optical qualities, and recyclability. Polycarbonate resin finds its uses in a wide range of end-use industries, such as electronics, optical media, building & construction, automotive, and medical equipment. The production of optical discs and rising consumer demand for electronics are expected to fuel market expansion. In the upcoming years, advancements in automobile glazing technology and medical equipment will further propel the polycarbonate resin industry. But growing applications of bisphenol A and carcinogenic residues, large upfront costs, trouble creating a strong marketing network, and licence acquisition could pose problems before the market. Furthermore, the growing danger of alternatives including co-polyesters, polystyrene, and polypropylene is hurting the growth of the polycarbonate resin market.

Limitations in the Polycarbonate Resin Market

A number of industrial restrictions impact the market for polycarbonate resin. Price swings for raw materials, particularly phosgene and bisphenol A, can have a significant impact on manufacturing costs and profit margins. Environmental concerns are another barrier, since the usage of bisphenol A and the production and disposal of polycarbonate resins have drawn regulatory attention and raised consumer worries about sustainability. Due to cost and environmental concerns, acrylics and bio-based polymers are also competitors in the market. The use of polycarbonate resin is complicated by its scratchiness, chemical sensitivity, and poor biodegradability. Processing problems include higher energy consumption and temperature requirements for manufacture. Recycling is further hampered by the intricate recycling procedure and the requirement for specialised facilities. The market dynamics will be further impacted by UV deterioration and challenges with regulatory compliance. To improve the material’s reputation in the face of shifting industrial and environmental expectations, innovative approaches, sustainable practices, and purposeful actions are needed.

Market for Polycarbonate Resin: Opportunities

The market for polycarbonate resin is expected to develop due to the material’s adaptability and applications. The market for polycarbonate resin is expanded by its use in the production of lightweight, impact-resistant automotive components. Automobile design is growing lighter in order to reduce emissions and improve fuel economy, which is good news for polycarbonate resin. Because polycarbonate resin is transparent and shatterproof, it is used in glazing and construction applications for safety and design flexibility. Exciting prospects arise from the use of polycarbonate resin in the production of LED lighting components, electrical housings, and consumer electronics. In these regions, the development of electric vehicles and 5G technologies is driving up demand for polycarbonate resin. Enhancements in formulation such as UV resistance and flame retardancy make outdoor and consumer goods applications possible. Bio-based and recycled polycarbonate resin can assist in achieving these objectives as sustainability gains importance. Strategic alliances and value chain partnerships can increase market potential by promoting creativity and novel applications. The market for polycarbonate resin is poised to take advantage of these prospects because of the material’s special qualities and shifting demands in the sector.

Key Market Drivers

- Growing Demand in the Automotive Industry: The automotive sector is a significant contributor to the polycarbonate resin market, driven by the need for lightweight materials that enhance fuel efficiency. Polycarbonate resins are increasingly used in automotive components such as headlight lenses, interior parts, and safety glasses. The ongoing trend toward light weighting in vehicle design and manufacturing supports the growth of the polycarbonate resin market.

- Expansion of the Electronics Sector: With the rapid advancements in technology and increasing demand for electronic devices, the need for high-performance materials like polycarbonate resins has surged. These resins are used in manufacturing housings, connectors, and components for smartphones, laptops, and other electronic gadgets due to their excellent electrical properties and impact resistance.

- Increasing Construction Activities: The construction industry’s growing demand for durable and lightweight materials has bolstered the polycarbonate resin market. Polycarbonate sheets are used in roofing, glazing, and interior partitions due to their excellent thermal insulation properties and UV resistance. As urbanization continues to rise globally, the demand for innovative building materials, including polycarbonate, is expected to increase.

- Healthcare Applications: The polycarbonate resin market benefits from its applications in the healthcare sector. Polycarbonate is used in the production of medical devices, sterilizable containers, and other healthcare products due to its biocompatibility and resistance to sterilization processes. The increasing focus on healthcare innovation and the demand for high-quality medical equipment support market growth.

Challenges in the Polycarbonate Resin Market

Despite its positive growth trajectory, the polycarbonate resin market faces several challenges:

- Environmental Concerns: The production and disposal of polycarbonate resins raise environmental concerns due to their reliance on fossil fuels and potential for environmental pollution. The growing awareness of sustainability and the push for eco-friendly alternatives may pose challenges for the polycarbonate resin market. Manufacturers are under pressure to develop more sustainable production processes and recyclable materials.

- Competition from Alternative Materials: The rise of alternative materials, such as glass, acrylics, and other advanced polymers, presents competition to polycarbonate resins. In some applications, these alternatives may offer better performance, lower costs, or enhanced sustainability. As the market evolves, polycarbonate manufacturers must innovate to maintain their competitive edge.

- Price Volatility of Raw Materials: The production of polycarbonate resin is dependent on raw materials derived from petrochemicals, making it susceptible to fluctuations in crude oil prices. Volatility in raw material costs can impact production margins for manufacturers and affect the overall pricing structure of polycarbonate resin in the market.

Regional Insights

The polycarbonate resin market is geographically diverse, with demand concentrated in several key regions:

- North America: The North American market is characterized by a strong presence of manufacturers in the automotive and electronics sectors. The growing trend toward lightweight materials and energy-efficient solutions supports the demand for polycarbonate resins in this region. Additionally, stringent regulations on vehicle emissions are driving the automotive industry’s shift toward lightweight materials.

- Europe: In Europe, the market is driven by the increasing focus on sustainability and energy efficiency. The construction and automotive industries are key consumers of polycarbonate resins, as manufacturers seek innovative materials that meet regulatory standards and environmental guidelines. The region’s commitment to reducing carbon emissions further supports the growth of the polycarbonate resin market.

- Asia-Pacific: The Asia-Pacific region holds significant growth potential, driven by rapid industrialization, population growth, and rising disposable incomes. Countries like China and India are major consumers of polycarbonate resin, particularly in the automotive, electronics, and construction sectors. The expanding manufacturing base and increasing demand for consumer goods contribute to the growth of the polycarbonate resin market in this region.

- Latin America and Middle East & Africa: These regions are experiencing moderate growth in the polycarbonate resin market, primarily driven by increasing construction activities and demand for consumer electronics. The ongoing urbanization and infrastructural development in these regions support the use of polycarbonate resins in various applications.

Competitive Landscape

The global polycarbonate resin market is competitive, with several key players actively engaged in production, research, and development. Major companies in the market include:

- Covestro AG

- SABIC

- Teijin Limited

- Mitsubishi Engineering-Plastics Corporation

- LG Chem Ltd.

These companies focus on expanding their product portfolios, enhancing production efficiency, and investing in research and development to introduce innovative solutions. Strategic partnerships, collaborations, and acquisitions are common as companies aim to strengthen their market position.

Future Outlook

The future of the polycarbonate resin market appears promising, with continued growth expected across multiple sectors. The increasing demand for lightweight and high-performance materials in automotive, electronics, and construction applications will drive market expansion. Additionally, advancements in production technologies and the development of sustainable materials will enhance the market’s growth potential.

As consumer preferences shift toward sustainable and eco-friendly solutions, manufacturers must adapt to evolving market dynamics. The ongoing innovation in polymer chemistry and the exploration of biodegradable and recyclable materials may offer new opportunities for growth in the polycarbonate resin market.

Conclusion

The polycarbonate resin market is set for steady growth, driven by its applications in the automotive, electronics, construction, and healthcare sectors. While challenges related to environmental concerns and competition from alternative materials may impact certain segments, the overall outlook remains positive. As industries evolve and consumer preferences shift, the polycarbonate resin market will adapt to meet the changing needs of a dynamic global landscape.

Contact Us:

Zion Market Research212

USA/Canada Toll Free: 1 (855) 465–4651

Newark: 1 (302) 444–016611\s

Web: https://www.zionmarketresearch.com/

Blog: https://zmrblog.com/