INTRODUCTION

Epoxy Coated TMT Bars: Revolutionizing Construction in Brazil

In the evolving landscape of construction materials, Epoxy Coated TMT (Thermo-Mechanically Treated) Bars have emerged as a game-changer, particularly in regions with challenging environmental conditions. In Brazil, where construction demands are on the rise, the adoption of epoxy-coated TMT bars offers numerous benefits that enhance the durability and longevity of structures. This blog explores what epoxy-coated TMT bars are, their advantages, applications, and the significance of choosing reliable manufacturers in Brazil.

What Are Epoxy Coated TMT Bars?

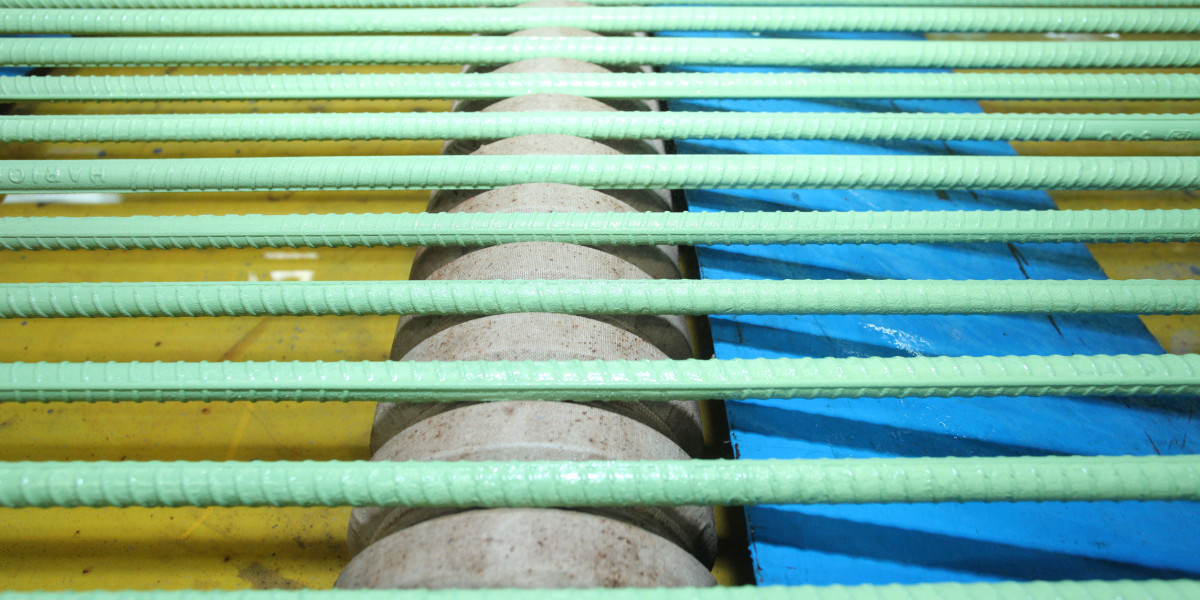

Epoxy coated TMT bars are reinforcement bars that have been treated with a protective epoxy coating. This coating provides an additional layer of protection against corrosion, making these bars ideal for use in harsh environments where moisture and chemicals are prevalent. The manufacturing process involves thermally treating the bars to enhance their strength and ductility, followed by applying an epoxy layer for added protection.

Advantages of Epoxy Coated TMT Bars

Corrosion Resistance One of the most significant advantages of epoxy-coated TMT bars is their superior resistance to corrosion. The epoxy coating prevents moisture and chemicals from coming into contact with the steel, significantly reducing the risk of rust and deterioration over time. This feature is particularly important in Brazil, where humidity and exposure to coastal conditions can lead to rapid corrosion.

Enhanced Strength and Ductility TMT bars are known for their high tensile strength and ductility, which allow them to withstand heavy loads and resist deformation. The combination of the TMT process and the epoxy coating ensures that these bars maintain their structural integrity under stress, making them suitable for various applications.

Reduced Maintenance Costs Structures reinforced with epoxy-coated TMT bars require less maintenance due to their corrosion-resistant properties. This reduction in maintenance not only lowers long-term costs but also minimizes downtime for repairs, making them a cost-effective choice for builders and contractors.

Environmentally Friendly The use of epoxy-coated TMT bars contributes to sustainable construction practices. By extending the lifespan of structures, these bars reduce the need for frequent repairs or replacements, leading to lower resource consumption and waste generation.

Improved Aesthetic Appeal The smooth finish of epoxy-coated TMT bars adds an aesthetic advantage to construction projects. Their sleek appearance is often preferred in exposed applications, contributing to the overall visual appeal of the structure.

Applications of Epoxy Coated TMT Bars

Epoxy-coated TMT bars are versatile and can be used in various construction applications, including:

- Bridges and Highways: Their corrosion resistance makes them ideal for use in infrastructure projects exposed to moisture and chemicals.

- Coastal Structures: Buildings and structures near coastal areas benefit from the protective qualities of epoxy-coated TMT bars.

- Industrial Facilities: In factories and plants where exposure to corrosive substances is common, these bars provide the necessary reinforcement.

- Residential Construction: Epoxy-coated TMT bars are increasingly used in residential buildings, ensuring long-lasting durability and safety.

Choosing Reliable Manufacturers in Brazil

When selecting epoxy-coated TMT bars for your construction projects in Brazil, it's crucial to choose a reputable manufacturer. Here are some tips to consider:

- Quality Certifications: Look for manufacturers with recognized quality certifications to ensure their products meet industry standards.

- Range of Products: A reliable manufacturer should offer a variety of TMT bar sizes and specifications to meet your specific project requirements.

- Customer Reviews: Researching customer feedback can provide insights into the quality and performance of a manufacturer’s products.

- Experience and Reputation: Established manufacturers with a strong track record in the industry are more likely to deliver high-quality products that meet your needs.

Conclusion

Epoxy-coated TMT bars are transforming the construction industry in Brazil, offering unparalleled durability and resistance to corrosion. By understanding the advantages and applications of these bars, construction professionals can make informed decisions that enhance the quality and longevity of their projects. Choosing the right manufacturer is crucial to ensuring that the epoxy-coated TMT bars meet the high standards required for successful construction.