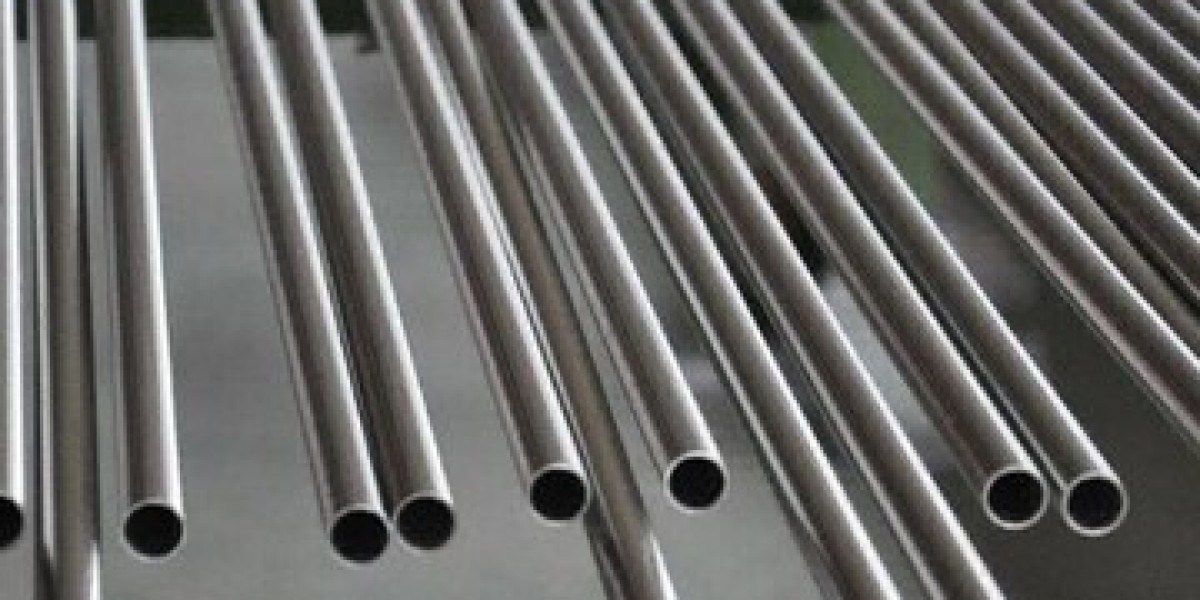

When it comes to industrial applications requiring precision and reliability, the selection of the right supplier for bright annealed tubes is critical. These tubes, known for their high-quality surface finish and excellent corrosion resistance, play a vital role in various sectors including automotive, aerospace, pharmaceuticals, and food processing.

1. Quality Assurance and Standards Compliance

The foremost consideration should be the quality of the bright annealed tubes. Suppliers should adhere to international standards such as ASTM (American Society for Testing and Materials), ASME (American Society of Mechanical Engineers), and DIN (Deutsches Institut für Normung). Ensuring that the supplier complies with these standards guarantees that the tubes meet rigorous quality criteria, offering reliability and performance in demanding applications.

2. Material Specifications

Bright annealed tubes are typically made from stainless steel, known for its durability and resistance to corrosion. It's important to verify the specific grade of stainless steel used, as different applications may require varying levels of strength, heat resistance, and anti-corrosive properties. Common grades include 304, 316, and 321 stainless steel, each suited for different environments and uses.

3. Manufacturing Process

Understanding the supplier's manufacturing process can provide insights into the quality and consistency of their products. The bright annealing process involves heating the steel in a controlled atmosphere furnace to achieve a bright, smooth finish and enhanced corrosion resistance. Ensure that the supplier employs state-of-the-art technology and has robust quality control measures in place throughout the manufacturing process.

4. Customization Capabilities

Every industry has unique requirements, and the ability to customize bright annealed tubes to specific dimensions, tolerances, and finishes can be crucial. A supplier with strong customization capabilities can tailor their products to meet your exact specifications, ensuring optimal performance in your specific application. This includes bespoke sizes, wall thicknesses, and surface treatments.

5. Supply Chain Reliability

A reliable supply chain is essential to maintain uninterrupted operations. Evaluate the supplier's capacity to deliver on time, their inventory management practices, and their geographic proximity to your location. Suppliers with a robust logistics network and sufficient inventory can mitigate risks associated with delays and stockouts, ensuring that you have a consistent supply of bright annealed tubes.

6. Technical Support and Service

Technical support is vital, especially when dealing with specialized products like Bright Annealed Tube. The supplier should offer comprehensive customer service, including pre-purchase consultations, technical advice, and after-sales support. This ensures that you have expert assistance available to address any issues or questions that may arise, enhancing the overall experience and satisfaction.

7. Reputation and Reviews

The reputation of a supplier can be a strong indicator of their reliability and product quality. Research reviews, testimonials, and case studies to gauge customer satisfaction. Positive feedback from other clients in your industry can provide confidence that the supplier has a proven track record of delivering high-quality bright annealed tubes.

8. Sustainability Practices

As sustainability becomes increasingly important, consider suppliers who prioritize environmentally friendly practices. This includes using sustainable raw materials, implementing energy-efficient manufacturing processes, and adhering to environmental regulations. Partnering with a supplier committed to sustainability can enhance your corporate responsibility profile and contribute to a greener supply chain.

Choosing the right supplier for bright annealed tubes requires careful consideration of various factors, from quality assurance and material specifications to supply chain reliability and sustainability practices. By conducting thorough research and evaluating potential suppliers based on these criteria, you can ensure that you receive high-quality products that meet your specific needs, ultimately contributing to the success and efficiency of your operations. Investing time in selecting the right supplier will pay off in the form of reliable performance, reduced downtime, and enhanced overall productivity.