Adhesives play a crucial role in the manufacturing of electric vehicles (EVs), contributing to their structural integrity, performance, and overall efficiency. As the automotive industry shifts towards electrification, the use of adhesives has become increasingly important in addressing the unique challenges and requirements of EV production. This article explores the essential role of adhesives in electric vehicle manufacturing, highlighting their benefits and applications.

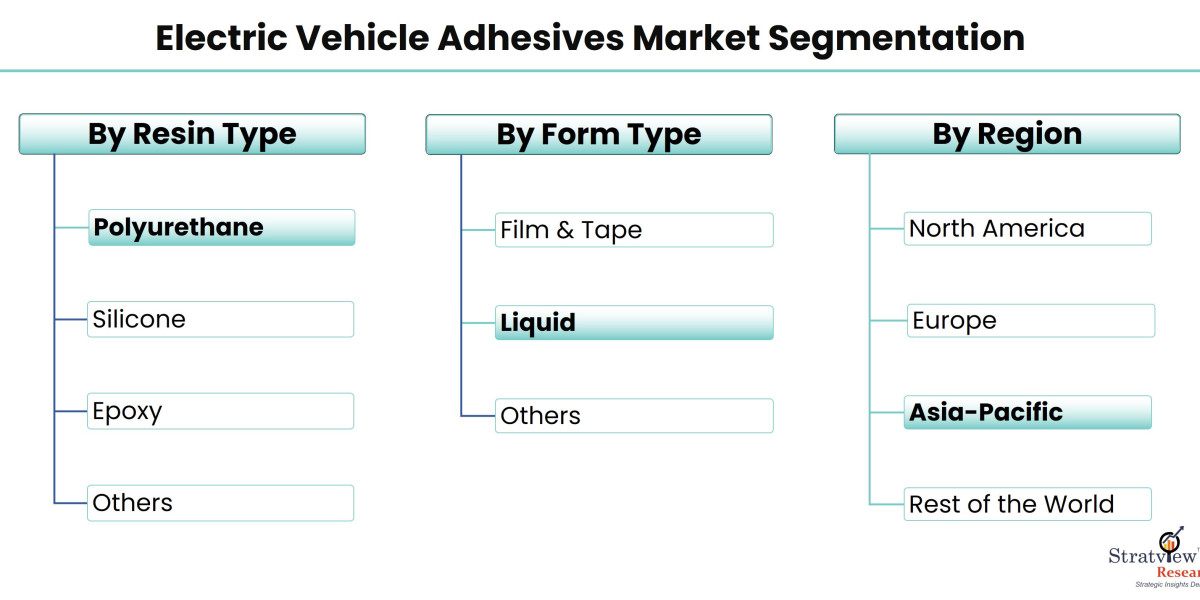

According to Stratview Research, the electric vehicle adhesives market was estimated at USD 1.38 billion in 2022 and is likely to grow at a CAGR of 40.04% during 2023-2028 to reach USD 10.61 billion in 2028.

Structural Integrity and Lightweighting

Adhesives are integral to achieving the lightweighting goals of electric vehicles. By bonding dissimilar materials such as aluminum, carbon fiber composites, and high-strength steel, adhesives distribute stress evenly across joints, enhancing structural integrity and reducing overall weight. This is critical for improving energy efficiency and extending the range of electric vehicles.

Enhancing Vehicle Safety

In EV manufacturing, adhesives contribute to the safety and crashworthiness of vehicles. They create strong bonds between components, reducing vibration and noise, and improving the overall stability of the vehicle. Adhesives also play a role in sealing joints, preventing water ingress, and protecting sensitive electronic components, which is particularly important for the longevity and reliability of electric vehicles.

Thermal Management

Electric vehicles require efficient thermal management systems to regulate the temperature of batteries, motors, and electronics. Adhesives are used to bond heat sinks, thermal interface materials, and other components that dissipate heat. This ensures optimal performance and extends the lifespan of critical EV components, contributing to overall vehicle reliability.

Noise, Vibration, and Harshness (NVH) Reduction

Adhesives help dampen noise and reduce vibration and harshness inside electric vehicles. By eliminating the need for mechanical fasteners, adhesives minimize the potential for squeaks and rattles, enhancing the comfort and driving experience for EV occupants.

Battery Pack Assembly

One of the most critical applications of adhesives in electric vehicles is in the assembly of battery packs. Adhesives bond cells together, ensuring a secure and compact arrangement while providing electrical insulation. This method not only reduces the weight of the battery pack but also simplifies assembly processes and enhances the overall safety of the battery system.

Environmental Benefits

Adhesives contribute to sustainability in electric vehicle manufacturing by enabling the use of lightweight materials and reducing energy consumption during production. They also facilitate the recycling of materials at the end of a vehicle's life, supporting a circular economy approach.

Conclusion

In conclusion, adhesives are indispensable in the manufacturing of electric vehicles, offering benefits such as improved structural integrity, enhanced safety, thermal management, NVH reduction, and environmental sustainability. As electric vehicle technology continues to evolve, the demand for advanced adhesive solutions will grow, driving innovation and efficiency in EV production. Manufacturers and suppliers are continuously developing new adhesive technologies to meet the evolving needs of electric vehicle manufacturers, making adhesives a critical component of the electric mobility revolution.